Ethanol Fuel

DDG Nutrient Testing

Grade Level: Middle School

The availability of nutrients is important to maintaining the diets of livestock to keep them healthy. Having the correct ratio of nutrients is important to ensure that feed nutrients are not wasted, not overfed, and that feed efficiency is optimized on the farm. Scientists use specialized testing protocols to determine the major components required for healthy growth and the development of livestock.

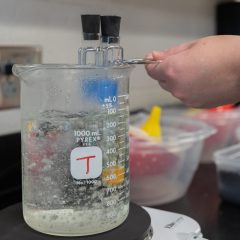

Fermentation is the process in which sugars are broken down and fed to yeast to produce ethanol and carbon dioxide. All the remaining nutrients: protein, fat, minerals, and vitamins, are concentrated into distillers grains, which is a valuable feed for livestock.

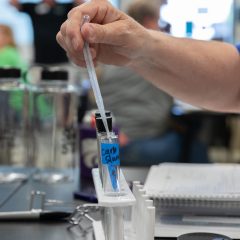

Our job today is to test where the most nutrient availability is located by comparing corn slurry (before fermentation) with fermented corn mash. In this lab we will be focusing on three of these major nutrients, glucose, starch, and protein, which are vital components for healthy livestock.

Teaching the Lesson

- Kansas College and Career Ready Standards

- Learning Objectives

- Materials

- Safety Considerations

- Procedures for Instruction

- Background Information

- Classroom Discussion

- Procedure for Lab

- Teacher Resources

- Lab Analysis

- Assessment

- Reflection and Conclusion

- Taking it Further (Optional)

- Science and Agriculture Careers

- Sources

- Disclaimer

About Kansas Corn STEM

Investing in Kansas teachers and students is a priority for the Kansas Corn Commission. We are committed to providing materials and training to support STEM education while fostering an understanding of how corn farming and agriculture fit into our daily lives. Professional development workshops are offered to teachers seeking to expand their knowledge and inquiry-based teaching skills. Workshop participants receive free lab supplies needed for the lessons.

Workshop InfoThis lesson is the work product of the Kansas Corn Commission. Our lessons are written in collaboration with Kansas teachers for use in the classroom. Teachers may copy and share this curriculum. Use of this product for commercial or promotional use is prohibited without express permission of Kansas Corn.

Newsletter Sign Up

Each quarter we release a newsletter written by teachers for teachers. This is an easy way to keep up with what is happening at Kansas Corn STEM.

Subscribe Today!