Ethanol Fuel

Corn Mash and Distillation

Grade Level: Middle School

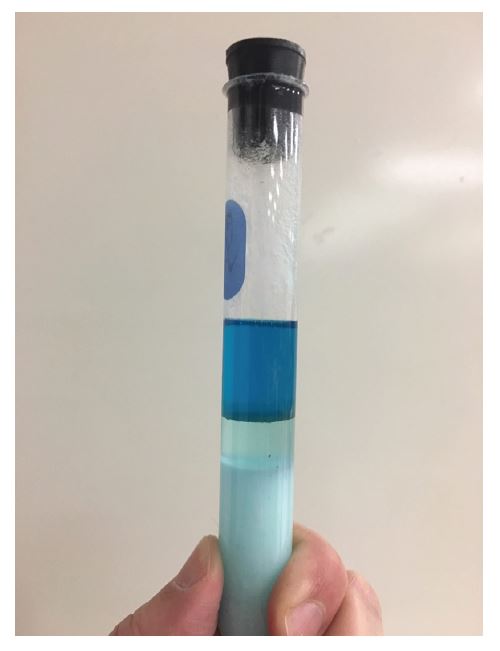

In this lab, students will learn about ethanol and its important role in our world’s ever increasing demand for energy. Students will go through the process of fermenting and distilling corn for ethanol production.

This lab has many variables that can affect ethanol production. The procedure can be followed as is, or a more inquiry-based lesson can be used by having students choose a variable and make changes to see how that variable affects the amount of ethanol produced.

Teaching the Lesson

- Kansas College and Career Ready Standards

- Learning Objectives

- Materials

- Procedures for Instruction

- Background Information

- Classroom Discussion

- Safety Considerations

- Procedure for Lab

- Teacher Demonstrations with Ethanol

- Teacher Resources

- Lab Analysis

- Reflection and Conclusion

- Assessment

- Science and Agriculture Careers

- Sources

- Disclaimer

About Kansas Corn STEM

Investing in Kansas teachers and students is a priority for the Kansas Corn Commission. We are committed to providing materials and training to support STEM education while fostering an understanding of how corn farming and agriculture fit into our daily lives. Professional development workshops are offered to teachers seeking to expand their knowledge and inquiry-based teaching skills. Workshop participants receive free lab supplies needed for the lessons.

Workshop InfoThis lesson is the work product of the Kansas Corn Commission. Our lessons are written in collaboration with Kansas teachers for use in the classroom. Teachers may copy and share this curriculum. Use of this product for commercial or promotional use is prohibited without express permission of Kansas Corn.

Newsletter Sign Up

Each quarter we release a newsletter written by teachers for teachers. This is an easy way to keep up with what is happening at Kansas Corn STEM.

Subscribe Today!