Every Drop Matters

Investing in the Future of Water

Kansas Corn continues to invest in research that aims to:

- Improve water use efficiency through plant analysis, genetic engineering and agronomic practices

- Protect water quality with cover crops, phosphorus management and improved fertilizer management

- Improve water use in irrigation by evaluating new technology and production practices

Kansas Corn

Testimonials

Investing in

Water Technology Farms

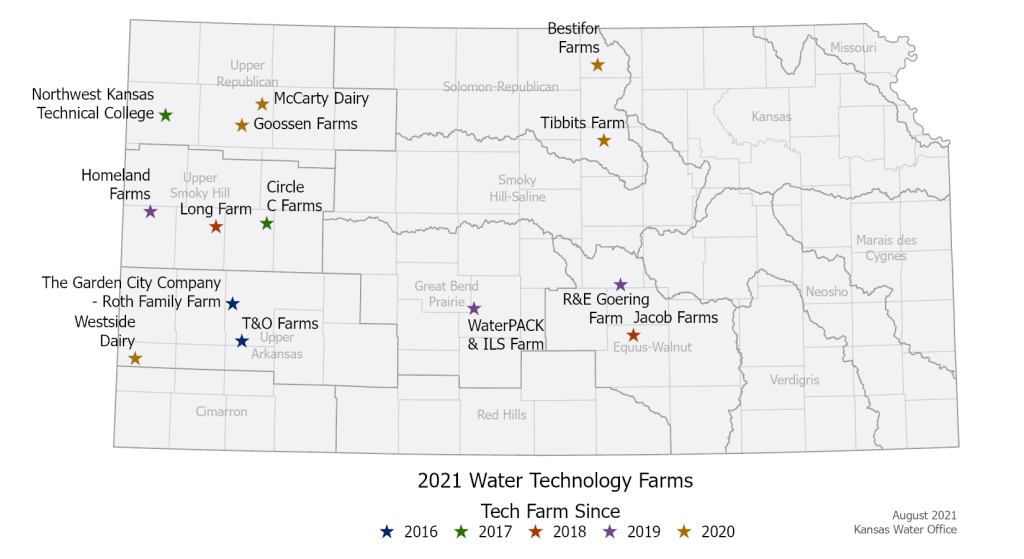

This year marks the fifth year of our partnerships with Water Technology Farm research program. This project, which started with three farms in 2016, has grown to include 15 farms spread across 14 different counties across Kansas researching both water quantity and quality issues. In 2019 we sponsored 7 of the 15 farms, helping obtain new equipment to test and then show at field days and other events throughout the year.

The Kansas Corn Commission funds many different research projects each fiscal year, but what makes this research so unique is the cooperation between public donors, private donors and especially the producers that donate their land, time and resources to help other producers gain more knowledge about the technologies available to increase irrigation efficiencies. Each corn field that we invest in for this project is later cut at harvest, sold to a first purchaser and then one cent per bushel comes back to the checkoff to help us fund research again for the next year. How many research projects can you say actually give money back to a sponsor each year?

-

Circle C Farms Scott County

Circle C Farms Scott County -

Hatcher Land & Cattle Farm Seward County

Hatcher Land & Cattle Farm Seward County -

Homeland Farm Greeley County

Homeland Farm Greeley County -

Jacob Farm Sedgwick County

Jacob Farm Sedgwick County -

Loess Hills Farm Doniphan County

Loess Hills Farm Doniphan County -

Long Farm Wichita County

Long Farm Wichita County -

Northwest Kansas Technical College Sherman County

Northwest Kansas Technical College Sherman County -

R&E Goering Farm McPherson County

R&E Goering Farm McPherson County -

The Garden City Company/ Roth Family Farm Finney County

The Garden City Company/ Roth Family Farm Finney County -

T&O Farms Finney County

T&O Farms Finney County -

WaterPACK/ILS Farm Stafford County

WaterPACK/ILS Farm Stafford County -

Weber Farm Harvey County

Weber Farm Harvey County